Near to us, in the historic market town of Clare, our artisan glassmakers at Suffolk Glass are busy making our exquisite range of beautifully reflective glass shades in clear, fluted, fine fluted, opal, ribbed and coloured glass designs for our ever expanding collections of lighting. The once family owned business has been making glass for customers across the country for 50 years and became part of the wider Jim Lawrence family in 2022.

Each and every piece of glass is expertly coaxed into life, taking around half an hour to create a clear shade and longer for a fluted one. We caught up with Ronda from Suffolk Glass to take a peek at what goes on behind the scenes at the busy workshop.

Welcome to the Style Journal Ronda. Firstly, can you tell us who makes up the Suffolk Glass team?I’m Ronda and I’m in charge of the day-to-day operations. Iwona is our quality control and packing expert and there are currently three glass blowers, Mark, Grant and Paul.

You have been making high quality glass products in Suffolk for over 50 years – can you tell us a little bit about the history of the business? Unfortunately, the original owners are not available to ask about the absolute beginning but in 1981 Suffolk Studio Glass, as we were once known, produced

artistic glassware and became renowned for its quality and craftsmanship. We made glass ships in bottles, miniature flowers in vases of all varieties and glowing glass candles that can still be found in homes to this day. As time progressed, we began making glass domes, scientific glass and then

glass light shades which is currently where we are now. We often get asked if we can reproduce broken or damaged lights that customers are unable to replace from other sources.

Given the length of time you have been making glass, there must have been a lot of changes over the years. What changes have affected the craft the most?

The overall process of how we make our glass shades has not changed much. We produce handmade glass, but technology and machines can produce lesser quality glass products much cheaper. I guess the real changes with glass blowing is that it’s very niche and sadly, a dying profession, so finding highly skilled blowers is difficult. How many people leave school or college and think of glass working as a career?

What is a typical day like at Suffolk Glass?

The blowers usually arrive around 7am and open the ovens ready for Iwona and me to empty and refill with products that are ready to go in - an ongoing ritual throughout the day. The blowers don’t stop until 5pm. As you can imagine, it’s extremely hot working with the burners and even more so in the hot weather!

Iwona quality checks each piece of glass before packing it, making sure the measurements are correct and overall appearance is excellent. As for myself, I answer customer emails and calls, deal with any queries, ensure we have the correct glass for the job, restock where necessary and provide quotes for bespoke and new enquiries. Really its up to me to ensure that everything runs smoothly and everyone is happy, which usually involves doughnuts and sausage rolls! We are a small team, but everyone gets on well and we just get on with the job in hand without too many problems.

Who are your glass blowers? What inspired you to be a glass blower and how did you get into the industry?

Mark: I went on holiday to the Isle of Wight when I was 16 and watched furnace blowing while there. I decided instantly that this is what I wanted to do and went to college to learn the art. I’ve been with Suffolk Glass now for 37 years.

Grant: I left school not knowing what I wanted to do, and a local glass company was hiring. Within a short time, I realised I was pretty good at it, and I progressed from making hour glasses to liquid nitrogen flasks to scientific glass. 14 years later, I had a career change but returned to glass blowing a few years ago. I find other people’s talent with glass quite fascinating. Suffolk glass is completely different to what I knew before and far more varied.

Paul: When I was 13 years old, I watched a live demo of bench working with glass and was really interested. My first job was in a scientific blowing factory, and they sent me to college to progress further. I’d been working with glass many years and recently returned to it here at Suffolk Glass.

We and our customers love the beautiful clear, fluted and fine fluted glass shades that you make. Can you talk us through some of the processes involved in making glass?

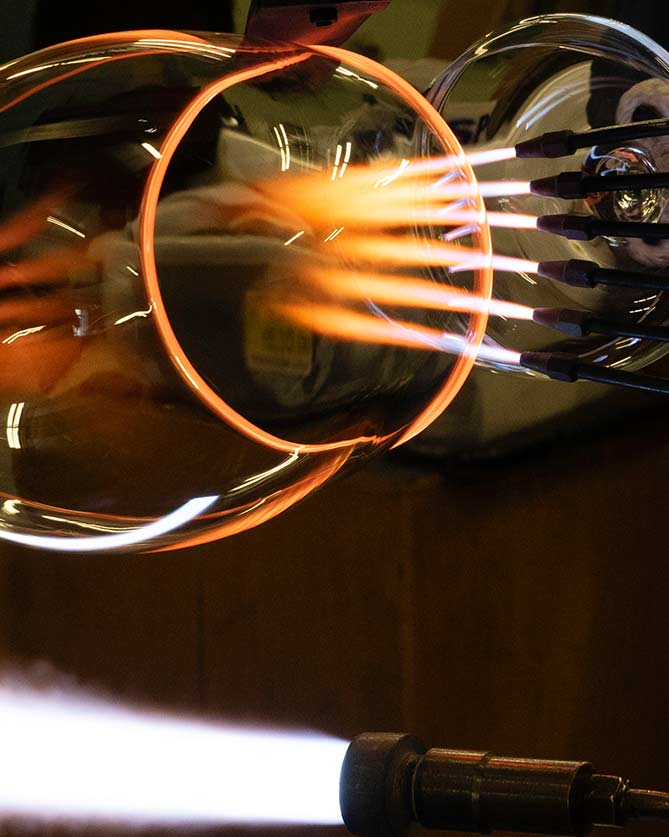

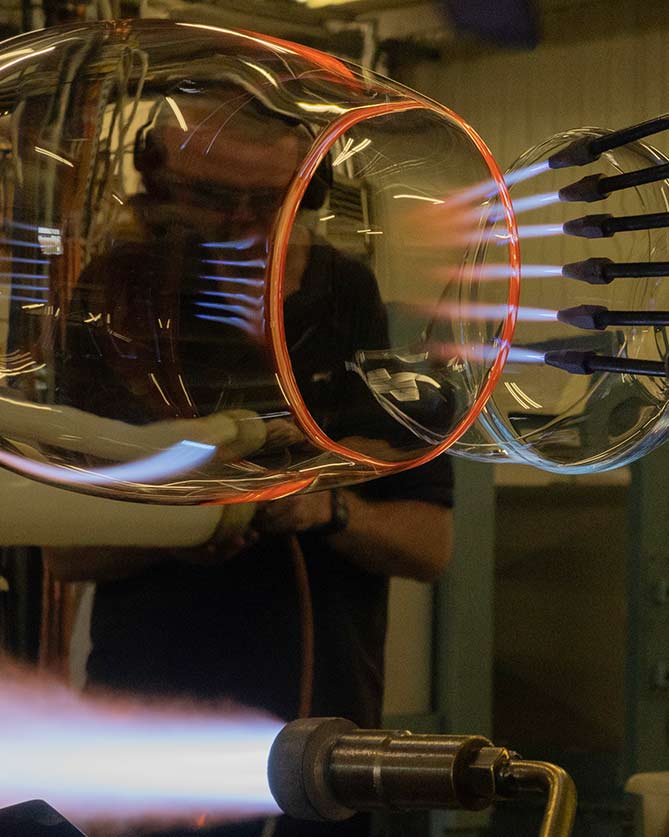

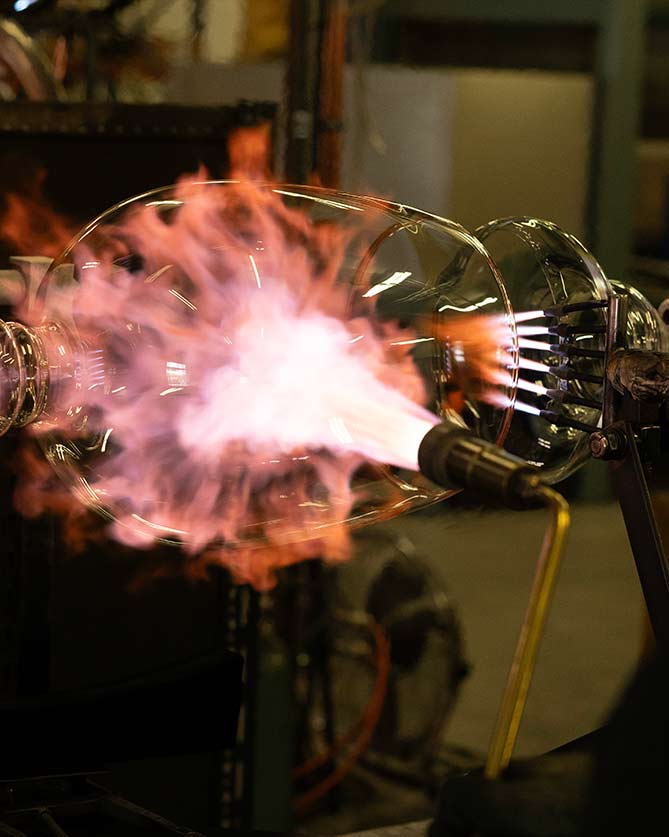

When people think of glass blowing, what comes to mind is usually furnace blowing and the use of a long blow pipe into the glass. That’s not us, we are lathe blowers, so basically, we put glass tubes into the lathe which we heat with burners and blow through a rubber hose connected to the tube. As the tube heats and is blown it expands, and the shape is formed using a carbon mould attached to the lathe.

The glass must not be allowed to touch the mould as this can cause blemishes on the glass. It is not an easy task to get the heated glass that close but not touch. The finished shade is then put into an oven which heats to around 580 degrees for half an hour before starting to cool down. This is the annealing process which allows the composition of the glass to relax after going through the stress of being worked. Without this annealing process, the strength of the glass would be affected.

How long does it take to create a glass shade? Do some take longer that others?

The length of time it takes depends on many factors including size and intricacy - even the ambient temperature in the workshop can affect glass blowing. During cold months the gas pressure is not as great as it would be during warmer times, so this means longer heating of the glass.

Roughly how many glass shades do you make in a day?

Once again, this is dependent on what is being produced. The Lansdown for example, takes an hour each, so approximately 10 pieces per day. Whereas the Morston wall lights can be produced at around 40 pieces per day.

Like many skilled crafts, it must be rewarding to be making something creative with your hands. What is your favourite part of the job and why?

Yes, it is very rewarding at times and particularly when producing something new and different for the first time. You do need to have a keen interest in working with glass and be proud of what’s produced. It’s always lovely when a customer contacts us with wonderful feedback and photos of their glass in situ.

What is your favourite glass to make and why?Mark enjoys making the domed shades, especially for the Bonham and Stafford lanterns. Paul prefers fluted pieces and doesn’t have a particular favourite yet although he likes making the Fluted Raydon. Being relatively new to Suffolk Glass, he hasn’t experienced making all the designs yet. Grant enjoys using coloured glass the most but likes making the Walcot and Fulbourn. These particular shades are quite easy to make, always turn out well and are pleasing on the eye.

Iwona also likes all the ribbed glass shades as she feels they offer something different, and the weight makes them feel even more classy. I personally like the Mia for its shape and cuteness. It’s different from a lot of the other lighting styles which can be very similar.