DefaultPageTemplate.ascx

CONDUIT GUIDE & FITTING INSTRUCTIONS

Our Universal Antiqued Brass conduit is a high-quality, reliable material commonly used in industrial as well as home and commercial settings. Available in a 20mm diameter our conduit tubes can be cut to lengths to meet the needs of a variety of applications. Learn more about its properties and what to consider when purchasing brass conduit.

WHAT TO CONSIDER WHEN CHOOSING ANTIQUED BRASS CONDUITS

When looking to purchase brass conduit for your project, there are a number of factors to keep in mind.

First, check the outside diameter (OD) of the material as it should match the inside diameter (ID) of the components you’re connecting.

Secondly, consider the length of the conduit you need: If purchasing conduit kit, ensure it’s long enough so you don’t have to disconnect when making connections or bends.

Good preparation and research before you start will save you a lot of time when installing conduit tubes

SAFETY FIRST

If in any doubt about electrical safety, contact a qualified electrician. Installation should always be carried out by a qualified electrician or a competent person in accordance with current electrical regulation.See the latest edition of British Standard 7671 for further information.

Please use earth connection point in junction box if present. The electricity supply should always be isolated at its source (fuse box) before attempting any installation or maintenance.

Ensure you have a strong fixing point when installing any part of the conduit system and use suitable fixings that are recommended for the intended mounting surface, taking into account both the individual and collective weight of components.

IP RATING

Any modification to this conduit system could potentially void the IP rating. If any O-Rings are damaged during the installation, replace with spares provided. Additional spare parts are available by visiting our website or showrooms.

For further details call the team on 01473 826699.

T

his conduit system is rated IP45, suitable for bathroom zones 2 and exterior use. For more information, please see our Knowledge Base Guides: IP Ratings Explained for Bathrooms

IP Ratings for Outdoors

HOW TO FIT OUR UNIVERSAL CONDUIT SYSTEM

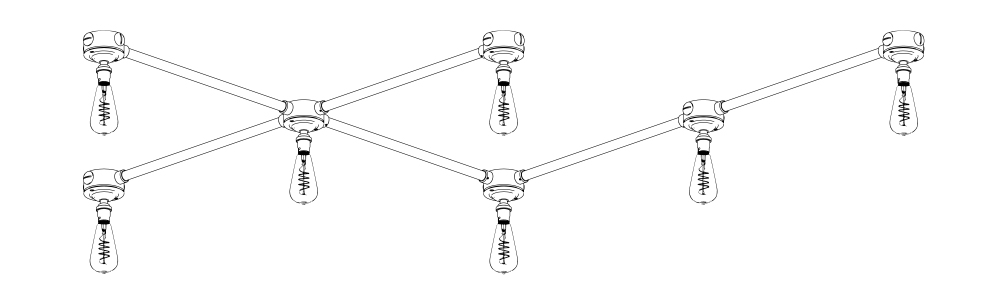

When installing multiple conduit accessories across a large space, we recommend you start by mapping out the position of all the main components first such as the lights, junction boxes etc.

This conduit system uses industry standard M20 threads and 20mm tube between all conduit fittings and junction boxes.

To join the conduit system into a compatible Jim Lawrence light an M16 coupler adaptor is required. Further information is available by visiting our website or showrooms, or call us on 01473 826699.

If using the conduit system in an IP23 or above rated environment, the O-Ring washers and locking M4 grub screws MUST be used.

When inserting tube into a coupler, take care to not damage the O-Ring. Ensure the end of the tube has no sharp edges and is deburred. To help the tube past the O-ring when inserting into a coupler, apply a small twist motion.

This Conduit System in designed in accordance with BS EN 61386-1:2008 and -21:2011. Classification code: 332110454112

STEP 1.

Ensure they all have solid fixing points are level with each other and you have a clear path to run the conduit tube.

Remember to position junction boxes anywhere where electrical connections are made allowing for maintenance if required.

STEP 2.

When you are happy with the positioning you can firmly fix these components to the wall following the relevant instructions for each item.

Then it’s a case of measuring the tube length between each component remembering to take off 2mm of length per coupler used.

STEP 3.

Once the tube is cut and deburred you can make the position of any supporting brackets and finalise the installation ready for any electrical cables to be installed.

STEP 4.

Once you have the correct size of brass conduit, you will need to assemble your installation.

Start by gathering all the necessary tools for the job.

STEP 5.

To join two pieces of conduit together, we recommend a push fit coupler.

This works by joining together with an integral O-Ring to ensure an IP seal, connectors or a coupling depending on your application.

STEP 6.

Make sure that when cutting down tubing, that you do not have rough or sharp edges.

Once aligned, the coupler can be tightened with an M4 locking screw.

STEP 7.

Where long pieces of tube are required, we recommend a maximum spacing of 100cm for unsupported tubes and positioning the brackets to support any joins, intersections and corners.

STEP 8.

The conduit brackets are designed to support longer lengths of conduit against the mounting surface.

The installation is very simple and requires x 3 screws. One to mount to the surface and two to hold the lid to the base.

T JUNCTION BOX

The T junction box allows for the termination and/or connection of the electrical cables with its removable sealed lid and integrated earth point. To remove the lid, unscrew the 2 screws located on the top.

Carefully remove the lid and accompanying seal.

Offer the junction box to the wall where you would like to fit it and mark the two fixing holes.

Drill and fit appropriate wall plugs if required. When screwing the junction box to the mounting surface, ensure the IP screw washers are in place.

The junction box comes with 2 blanking caps and 1 open entry point.

When removing a blanking cap, ensure you retain the O-Ring for future use.

4 WAY JUNCTION BOX

The 4 way junction box allows for the termination and/or connection of electrical cables with its removable sealed lid and integrated earth point. To remove the lid, unscrew the 4 screws located on the top.

Carefully remove the lid and accompanying seal.Offer the junction box to the wall where you would like to position it and mark the two fixing holes.

Drill and fit appropriate wall plugs if required. When screwing the junction box to the mounting surface, ensure the IP screw washers are in place.

The junction box comes with 3 blanking caps, 1 open entry and an IP rated grommet in the back of box.

If bringing a supply cable through the rear IP rated grommet, pierce a small hole only, to ensure a sufficient seal around supply cable.

When removing a blanking cap, ensure you retain the O-Ring for future use.

COUPLERS

This conduit system works via a series of push fit couplers to join tube between junction boxes, lights etc. These couplers have an internal O-Ring that presses against the tube, creating an IP seal.

Before inserting tube into the coupler, ensure the end of the tube has no sharp edges or burrs. Remove with a suitable metal file if required.

Align the tube centrally of the coupler and firmly push into place. The tube will bottom out inside the coupler and go no further when done correctly.

Tighten the M4 locking screw to ensure the tube remains in place. If the M4 screw isn’t accessible once the coupler is tight against junction box / light etc, back wind the coupler until you can access the locking screw.

Once tightened, firmly tighten the coupler back against the O-Ring.

CABLE GLAND FITMENT

The cable gland fitment allows the entry of a supply cable into either the 4 way or T junction box.

Carefully screw the gland base into the junction box, ensuring the O-Ring is sandwiched between both parts.

Fully tighten to ensure sufficient IP rating.

Remove both the gland nut and gland and feed the supply cable through all components into the junction box.

Push the gland firmly into the base and fully tighten to ensure gland seals around cable.

ELBOW

The conduit elbow is a non accessible 90 degree angle connector that works by screwing a coupler into each end.

It is recommended a bracket or junction box is spaced within 40cm of either end of the elbow for support.

Ensure the O-Ring is placed between coupler and elbow for IP purposes

BRACKET

The conduit bracket is designed to support longer lengths of tube against the mounting surface.

We recommend a maximum of 100 cm of unsupported tube and/or positioning brackets to support any joins, intersections of corners.

Special consideration on a bracket placement may be needed for high traffic areas.

HOW TO FIT THE CONDUIT CEILING ROSE

Before installing the light, switch off the mains electrical supply. If required, disconnect and remove your existing light making note of how the wires are positioned and connected.

STEP 1.

Unscrew the rose plate from the lumninaire by removing the two plate screws either side of the lamp holder.

STEP 2.

Offer the backplate to the wall or ceiling where you would like to position the light, ensuring you have a strong fixing point – a ceiling joist is ideal.

STEP 3.

Mark and drill the holes for the fixing screws taking care not to damage any electrical cables. Insert wall plugs or additional fixings if required.

STEP 4.

Screw the backplate to the ceiling using the screws supplied, ensuring you feed your existing supply wires through the centre hole grommet of the backplate if required.

STEP 5.

If using in conjunction with the Jim Lawrence Conduit system, carefully unscrew the relevant blanking cap that allows for the conduit coupler and tube to be threaded into the backplate.

STEP 6.

Feed your supply wires through conduit tube and into the backplate. Next, connect the lampholder to your supply wire. We recommend you use the supplied connector blocks within the backplate to connect to the supply wire

STEP 7.

Ensure the cables are fully inserted into the connector blocks and connect the wires in accordance with the wiring diagram.

STEP 8.

Ensure the earth cable attached to the backplate is attached to the connector block. If any doubt, please contact a qualified electrician

STEP 9.

Once correctly wired, place the rose plate centrally over the backplate and tighten the plate screws, ensuring that all the wires are located within the light.

STEP 10

If you are intending to use a shade with this ceiling rose, it is now time to do it. For Jim Lawrence shades with a built in thread, simply screw these onto the lampholder thread. For any other shade type, please use the shade ring to secure in place.

These instructions apply to fitting the Conduit Ceiling Rose Light that is intended for indoor use only.

REPLACEMENT PARTS

Call Us

If you are looking for replacement parts for your conduit system, please call the Customer Services Team on 01473 826685 with your requirements and we will be able to help you.

Email Us

If you would like a quote, or any advice you can also email us at: sales@jim-lawrence.co.uk and someone from our helpful Customer Services Team will get in touch.